THANK YOU FOR SUBSCRIBING

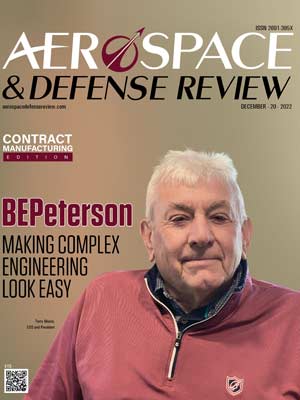

Terry Moore, CEO and President and Dan Szczurko, VP of Business Development

Terry Moore, CEO and President and Dan Szczurko, VP of Business DevelopmentBEPeterson is one of the few companies that have mastered this engineering harmony to successfully make large-scale industrial equipment for many different industries. It has evolved into an engineering powerhouse that particularly serves the aerospace and defense industry.

Whether pressure vessels, skid assemblies, vacuum chambers, or developing a design concept from scratch, BEPeterson has the expertise, equipment, materials, and facilities to meet diverse needs. It is aware that many businesses seek customized turnkey solutions. This is possible if they work with a partner like BEPeterson, skilled at building and operating complex machinery and interpreting the customers exact expectations to deliver the desired solution safely.

BEPeterson is unique among fabricators because of its contract manufacturing capabilities. Its team of engineers possesses a high level of expertise and integrity in engineering. “As the projects we’ve undertaken have grown in size and complexity, we invested heavily in our engineering team to match the ever-changing requirements,” says Dan Szczurko, VP of business development of BEPeterson.

BEPeterson has an extensive list of credentials and certificates— including ISO-2015 certification—which enables it to seamlessly address various engineering parameters. Its rich experience and expertise effectively bridge the gap between expectations and the project’s technical feasibility. For this reason, it works with the US Navy, Airforce, and federal government to develop some of the most complicated test systems.

BEPeterson processes over 2,500 tons of material in a year. In large-scale manufacturing, material cost is the biggest pebble in a client’s shoe. Operating in the industry for many decades, BEPeterson has built a reputation for securing materials of the highest specifications at the lowest price. It gives credit to its innovative and knowledgeable engineering team, who understand the need for industrial-grade materials and their interaction with different industries.

BEPeterson has expertise across numerous markets. A thing that remains constant across all projects, however, is its ability to forge strong partnerships

For instance, BEPeterson recently received a purchase order for 28 replacement air flask vessels from Military Sealift Command in Norfolk. These replacement vessels will be installed on the USNS Laramie, a Henry J Kaiser class replacement oiler serving the United States Atlantic Fleet. The air flask vessels manufactured by BEPeterson are DFARS-compliant and require high-quality welding to tight tolerances.

“BEPeterson has expertise across numerous markets. A thing that remains constant across all projects, however, is its ability to forge strong partnerships,” says Terry Moore, CEO and President of BEPeterson. The company treats customers as partners and never shies away from using its multidimensional expertise to support them in their journey. It credits this confidence to its longevity, incorporated in 1935, enabling it to understand and anticipate customer needs.

In the coming years, BEPeterson will continue to take on complicated and exciting projects pushing the envelope and meeting the engineering and fabrication challenges that lie ahead in a technologically evolving world. As such, BEPeterson will keep investing in its engineering team to develop a new generation of products to help businesses and individuals worldwide.

| Share this Article: |

BEPeterson

Company

BEPeterson

Management

Terry Moore, CEO and President and Dan Szczurko, VP of Business Development

Description

BEPeterson is the leading manufacturer of custom metal fabrication of heavy-gauge metal parts and equipment.