THANK YOU FOR SUBSCRIBING

For the last seventy years, WAKITA HI-TECS has been a leading manufacturer of transport and storage containers for high-stakes defense equipment, involving large-scale machinery and hazardous materials. Driven by a commitment to quality, safety, and reliability, the company has served global giants, including Mitsubishi Heavy Industries and Kawasaki Heavy Industries. It has also supported key public sector institutions, such as Japan’s Ministry of Defense, not just as a supplier, but as a partner. The true engine behind WAKITA HI -TECS’ reputation is not just its products, but the people crafting them. From the moment a new recruit steps in, they embark on a structured immersion in craftsmanship, rotating through welding bays, machining centers, and quality-control stations. This hands-on training instills not just mastery in equipment and tolerances but a deeper, zero-defect mindset. Complementing this, the company runs a fully independent inspection system, structurally separate from the production team, which ensures no product leaves the factory unless it meets strict defense-grade criteria. This internal culture of excellence enables the company to work in sync with clients long before formal specifications are even finalized. Where many manufacturers wait for fully defined blueprints, WAKITA HI -TECS engineers dive in at the earliest conceptual stages. They leverage institutional knowledge and previous design insights to sketch rough drafts, simulate performance in-house, analyze materials, and provide viable alternatives. This level of collaboration allows the company to meet compressed timelines without compromising technical integrity. Built on Talent, Driven by Systems What differentiates WAKITA HI -TECS is not just precision machinery and craftsmanship-oriented training, but its commitment towards the holistic development of its employees. “We consider the development of excellent leadership talent to be important. It is our value that everyone involved with our company leads a wonderful life,” states Daiki Wakita, the president of WAKITA HI -TECS. This philosophy is implemented through mentorship programs, Kaizendriven workshops, and project leadership opportunities. Employees are expected to meet specifications and are encouraged to think critically, ask questions, and continually improve processes. In parallel, the company has institutionalized excellence through structure. Its dedicated inspection department, strict internal processes, and alignment with defense manufacturing standards ensure that even under deadline pressure, quality is never compromised. After-sales services, overhauls, and repair capabilities further reinforce this commitment to long-term performance and client satisfaction.

Jamming System in Apac 2025

In a world increasingly dependent on wireless communications, the distinction between safety and vulnerability blurs with each technological advancement. Jammers4u, an original equipment manufacturer (OEM) and exporter of wireless solution technology equipment, is at the forefront of developing customized jamming solutions for security, government, and military and defense applications. “At Jammers4u, we assist clients design jamming systems according to the specific frequencies, channels, and coverage requirements of each project,” says Anthony Dragon, Sales Director. The firm’s continuous investment in research and development (R&D) has resulted in an impressive portfolio of advanced jamming technologies. From multi-band high-power systems to versatile indoor and outdoor solutions, Jammers4u’s offerings are designed to protect critical assets in various high-risk environments. These include mobile, GPS, drone, and wireless camera jammers that are crucial for ensuring the safety of military convoys, governmental facilities, and other high authority operations. Tracing its roots back to 2004 as an initiative of the R&R Group, Jammers4u has undergone a remarkable evolution. Initially a pioneer in radio frequency (RF) manufacturing in Taiwan, the company has since expanded its reach globally, setting the standard for wireless security solutions. The R&R Group’s expertise in OEM production of specialized wireless security equipment and signal jammers has secured Jammers4u’s position as a leader in RF jamming technology.

Military Port Agency in Apac 2025

Inchcape Shipping Services’ history of supporting many marine clients in the commercial and defense sectors stretches back over 177 years. A journey that began in 1847 in Campbeltown, Scotland, with a general merchant partnership has now expanded to become one of the world’s largest and most respected shipping service providers. With more than 247 proprietary and joint venture offices across 60 countries, supported by 3,200 employees and an unparalleled integrated network of accredited service providers, Inchcape offers its clients a truly unique experience on a global scale. Imagine a world where you don’t have to juggle multiple contacts, navigate varying regulations, and manage the nuances of local markets on your own. Inchcape brings this world to life. From this central hub in Dubai, contracts, invoicing and operational tasks are efficiently allocated to regional specialists. They guarantee the flawless execution of services, irrespective of the location’s challenges—ranging from the remote expanses of Antarctica to the rigorous landscapes of Africa. This cohesive service approach plays a key role in operations critical to national security, international peacekeeping and global humanitarian efforts. As such, it stands as an indispensable ally to the Armed Forces and NGOs due to the sensitive nature of their operations, which necessitates steadfast compliance with stringent standards. “With almost two centuries of existence, we not only recognize the importance of compliance as a cornerstone of reliability and commitment but integrate it as one of our values,” says Nicolas Wauters, VP of government services at Inchcape Shipping Services.

CXO INSIGHTS

Supporting Sustainability in Aviation

Bonny Simi, President of Operations, Joby Aviation [NYSE: JOBY]

Modernizing the Aviation and Defense Sector

Natthawat Hongkarnjanakul, Space Innovation Development Expert, GISTDA

Changing Technologies in the Aviation Sector

David So Man Fung, Senior Vice President, Corporate Planning & Continuous Improvement, SIA Engineering Company (SGX: S59)

Navigating Aircraft Maintenance Quality Challenges: Insights from a Quality Manager

Ben Osborn, Head of Airworthiness Compliance, Northrop Grumman (NYSE: NOC)

Developments in Aircraft Architecture Design

Thomas Ahn, Chief Engineer D328eco, Deutsche Aircraft

Airport Management Innovations: Navigating Challenges Effectively

Abe Weber, Airport Director, Appleton International Airport

IN FOCUS

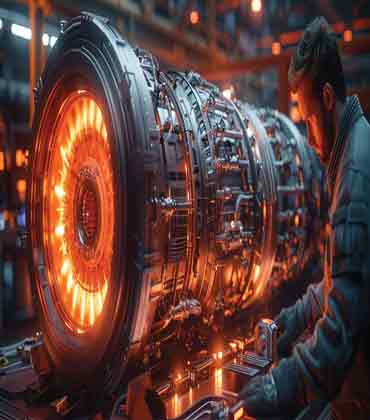

Future of Manufacturing with Precision Machinery and Equipment in APAC

AI is revolutionizing precision machinery in the APAC region, driving efficiency and quality. Despite challenges like legacy systems and costs, strategic investments and collaboration are key to successful adoption.

Driving Aerospace Innovation in APAC through Precision Engineering

Aerospace precision equipment enhances safety and efficiency by ensuring accurate manufacturing and reducing errors. This improves performance, saves costs, and extends the lifespan of both manned and unmanned platforms.

EDITORIAL

Precision Machinery Driving the Next Wave of Manufacturing

At the center of this transformation are precision machinery and equipment manufacturers. Once niche players operating in the background, they are now vital enablers of the region’s global competitiveness. These manufacturers supply ultra-high tolerance machining tools, sensor-integrated automation systems, and digitally controlled production lines that are elevating standards across sectors.

From CNC machining centers in Japan and optical inspection systems in South Korea to smart robotics and motion control technologies in Singapore and Taiwan, APAC has firmly established itself as a global leader in precision engineering. What sets these manufacturers apart is not just the quality of their machines. It is their ability to customize solutions, integrate AI-driven control systems, and meet increasingly stringent sustainability requirements while supporting a diverse, fast-changing client base.

In sectors where a single micron can determine a product’s viability or failure, these manufacturers form the invisible infrastructure behind industrial progress. Their machinery enables high-speed, high-volume production of complex components with near-zero defects, optimized energy use, and data-rich performance monitoring.

As the region intensifies its focus on reshoring, industrial resilience and greater supply chain autonomy, precision equipment is more than a technical solution, it is a strategic advantage that empowers manufacturers to compete globally with confidence.

In this edition, we feature insights from WAKITA HI-TECS, a leader in high-precision solutions, alongside Chris Allan, Director Accounts & Partnerships, NATS, and Duane Cornella, Sr. Manager, Operations Control Centers, Panasonic Avionics, for their insights into APAC’s precision manufacturing landscape.

However, if you would like to share the information in this article, you may use the link below:

https://www.aerospacedefenserevieweurope.com/edition/august-september-2025-38.html